Medical PCB Assembly: Precision, Reliability, and Safety for Life-Critical Devices

The healthcare industry depends on accuracy, reliability, and flawless performance. Whether in diagnostic equipment, patient monitoring systems, imaging devices, or life-support machines, every electronic component plays a crucial role in patient care. At the heart of these medical electronics lies the medical PCB assembly, a highly specialized manufacturing process that requires strict quality control, advanced production techniques, and full compliance with global medical standards. As devices become smaller, smarter, and more interconnected, the need for dependable medical PCB assembly has never been greater.

Understanding Medical PCB Assembly

What Makes Medical PCB Assembly Unique

Medical PCB assembly refers to the production of printed circuit boards specifically designed for medical devices, where precision and stability are non-negotiable. Unlike general electronics, medical applications demand extreme reliability, long-term durability, and stringent testing because even the slightest malfunction can directly impact patient health. These boards must operate flawlessly in environments with high temperatures, moisture, chemical exposure, and electromagnetic interference.

Medical PCB assemblies also involve a wider range of materials and layouts, from multilayer PCBs to rigid-flex designs, high-density interconnects, fine-pitch components, and embedded technologies. The entire process—from choosing the PCB substrate to soldering sensitive components—must follow strict medical industry standards such as ISO 13485, IPC-A-610 Class III, and FDA design and manufacturing guidelines.

Importance of Accuracy and Safety in Medical Devices

Every heartbeat monitor, infusion pump, wearable health sensor, and surgical instrument relies on a PCB that works consistently. A single defective solder joint or misaligned component can cause inaccurate readings, device failure, or life-threatening issues. Therefore, medical PCB assembly places major emphasis on defect-free manufacturing, traceability of materials, and adherence to product specifications across every production batch.

Materials Used in Medical PCB Assembly

High-Grade Substrates and Specialized PCB Types

Medical devices often require advanced PCB materials that offer stability, electrical performance, and environmental resistance. Boards may be fabricated using high-Tg laminates, ceramic materials, or flexible polyimide substrates. For example, wearable medical sensors rely on flexible PCBs that can bend without losing connection, while implantable devices require biocompatible substrates with zero contamination risk.

Multilayer PCBs are also widely used because they allow greater component density and compact medical device designs. Rigid-flex PCBs are ideal for portable monitoring systems, imaging equipment, and cardio devices where space optimization is essential.

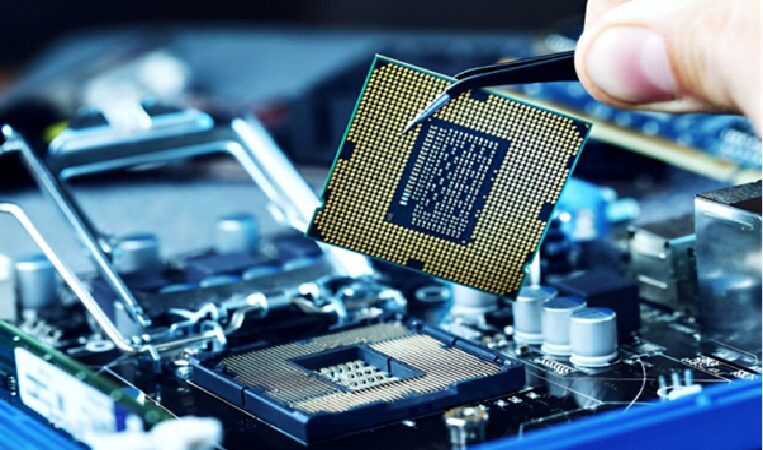

Component Selection for Medical Precision

Sensors, microprocessors, connectors, wireless communication modules, and power components must all meet medical-grade reliability standards. Components used in medical PCB assembly often need to withstand sterilization cycles, radiation exposure, or extreme temperatures. This requires manufacturers to choose parts with extended lifecycle support and verified traceability to prevent counterfeit or low-quality components from entering the assembly line.

Manufacturing Process of Medical PCB Assembly

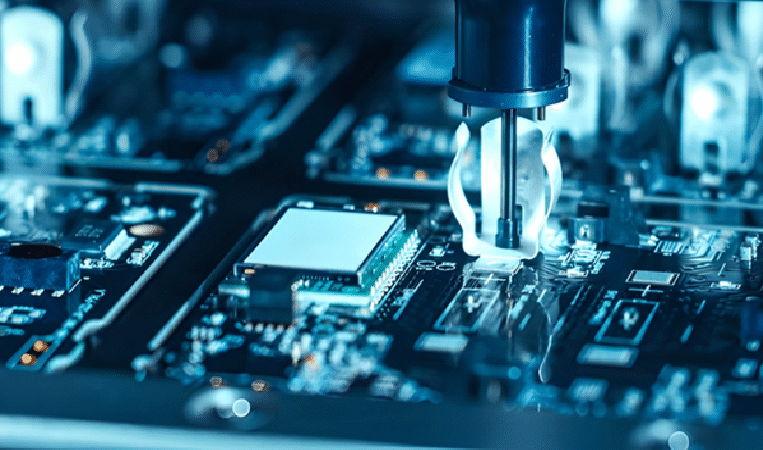

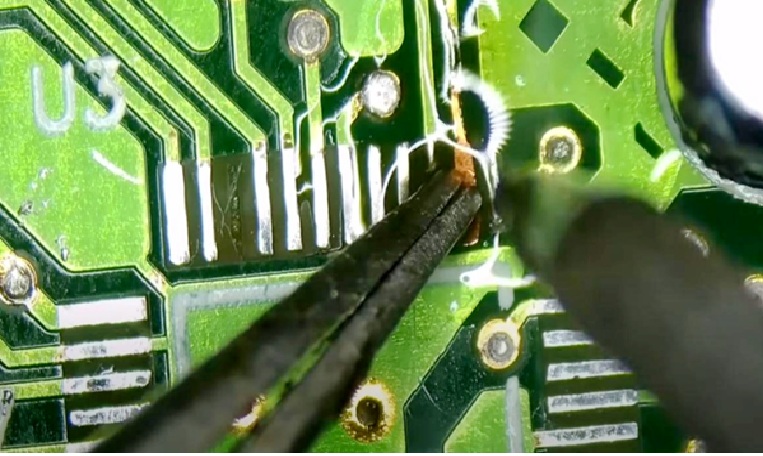

High-Accuracy Soldering and Placement

In medical PCB assembly, ultra-fine components such as micro-BGAs, QFNs, 01005 resistors, and miniature ICs are common. High-precision pick-and-place systems ensure exact placement, while controlled solder deposition ensures consistent joints. Solder paste printing must be carefully calibrated to avoid defects such as voids, insufficient solder, or bridging, as these issues can compromise the device’s long-term performance.

Advanced Reflow and Thermal Profiling

Reflow soldering is optimized using precise thermal profiles designed for sensitive medical components. Boards with temperature-sensitive sensors or microchips require carefully controlled heating zones to prevent damage. Manufacturers often use nitrogen reflow systems to increase solder joint reliability and reduce oxidation.

Through-Hole Technology and Selective Soldering

Where mechanical strength is essential, through-hole components are soldered using selective soldering machines to maintain consistency. Medical power supply boards, connectors, and larger components benefit from this method because it provides additional strength and long-lasting durability.

Inspection and Validation

Quality control is the core of medical PCB assembly. Every step undergoes monitoring using advanced inspection technologies such as 3D AOI, X-ray inspection for hidden joints, and functional testing tailored to the specific device. Manufacturers also perform burn-in tests, durability tests, and environmental stress tests to ensure the PCB can withstand real-world medical use.

Applications of Medical PCB Assembly

Diagnostic Devices

Blood analyzers, ECG machines, ultrasound devices, and imaging systems rely on stable, high-performance PCBs. These assemblies ensure accurate readings and responsive performance that medical professionals rely on.

Patient Monitoring Systems

Continuous monitoring devices require PCBs with ultra-low power consumption, wireless communication capability, and long-term reliability. Wearables for heart rate, blood oxygen, and glucose monitoring use flexible and compact PCBs designed for comfort and precision.

Therapeutic and Surgical Equipment

Infusion pumps, ventilators, surgical navigation systems, and robotic surgery tools depend heavily on highly reliable PCB assemblies. Failure is not an option in these life-critical applications.

Implantable Medical Devices

Pacemakers, hearing implants, neurostimulators, and insulin pumps require miniaturized, biocompatible PCBs that must operate flawlessly for years. The medical PCB assembly for these devices is among the most advanced in the electronics industry.

Why Manufacturing Excellence Matters in Medical PCB Assembly

A reliable medical PCB assembly process ensures safety, regulatory compliance, and long-term device performance. Because the stakes are so high, manufacturers must combine advanced technology, skilled technicians, verified supply chains, and thorough testing procedures. When these factors come together, medical devices achieve longer lifespans, fewer failures, and accurate patient data—ultimately improving quality of care.

Conclusion: Build Your Next Medical Device with Confidence

If you need dependable, high-precision medical PCB assembly, partnering with a trusted manufacturing expert is the key to producing safe, reliable, and compliant devices. Whether you’re developing diagnostic equipment, wearable monitors, or life-saving medical systems, choosing a manufacturer that excels in PCB assembly services ensures consistent quality, fast turnaround, and full support from PCB fabrication to final assembly.